We can colaborate with our clients designing and manufacturing first prototypes with fast methods (stereolithography, laser-sintering), continuing with the elaboration of small trainning series for tests and finaly applicating in an automatic assembling line for production of big series.

Some of our customers choose to delegate the total management of their product which involves plastic injection, welding, additional assembles and finally electrical assays and final controls.

Technical and logistical collaboration

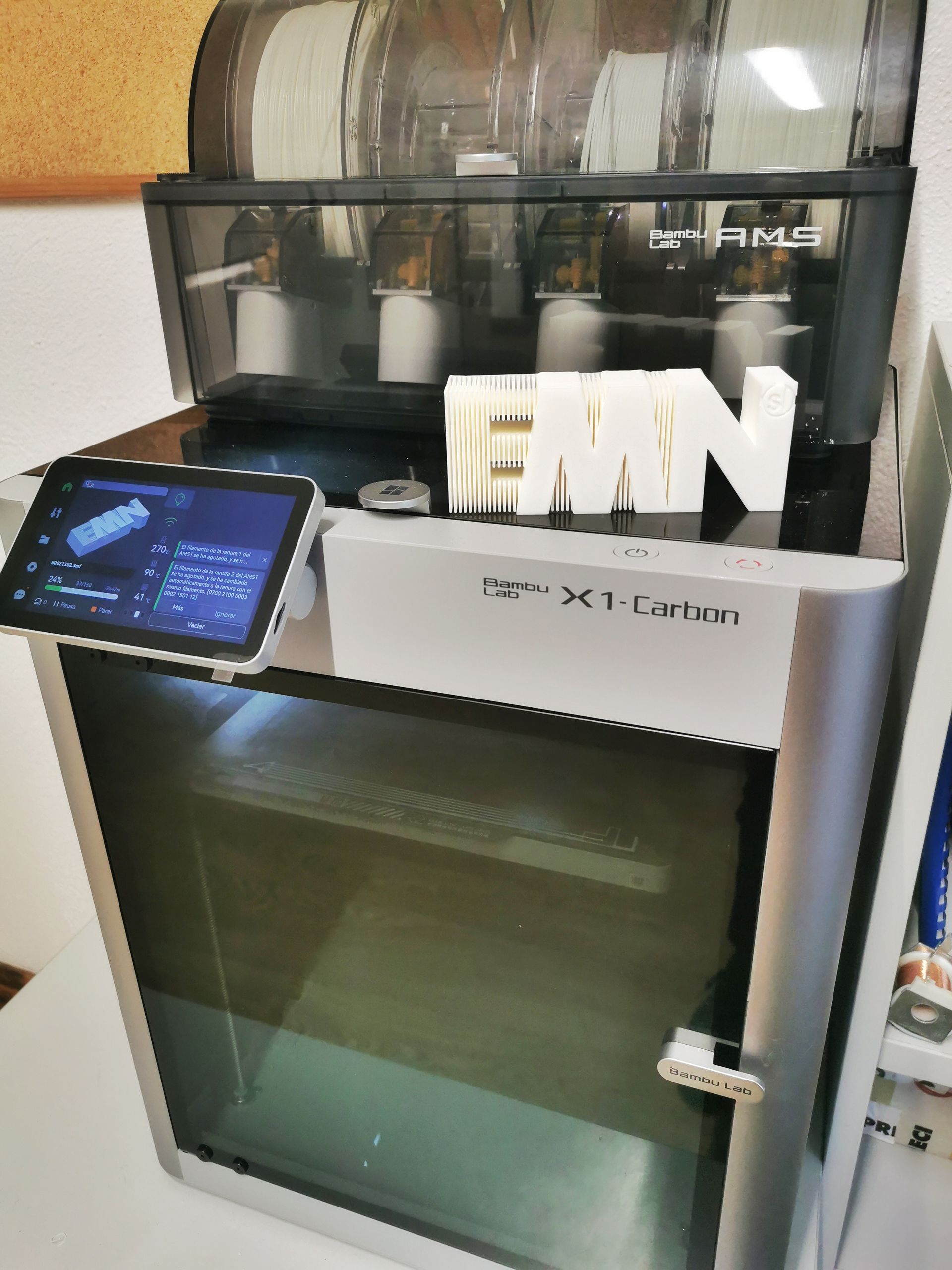

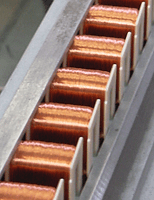

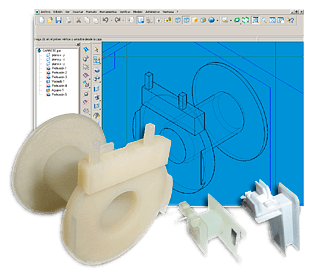

Finally we wind the prototype coils so the client gets, in a short time, models or short series of finished coils of functional materials, destinated to testings with the posibility of improving the coil design before invest on expensive injection moulds.

We count with 3D software such as Solid Edge and 3D printer for the design and prototyping phase.